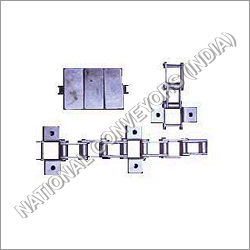

Industrial Bulk Flow Chain

Price 170.00 INR/ Piece

Industrial Bulk Flow Chain Specification

- Material

- Alloy Steel

- Metal Type

- Steel

- Fence Type

- Industrial Bulk Flow Chain

- Frame Type

- Chain Assembly

- Fence Width

- Customizable as per requirement

- Fence Length

- Custom Lengths Available

- Application

- Bulk material handling in industrial conveyors

Industrial Bulk Flow Chain Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 10-15 Days

About Industrial Bulk Flow Chain

Bulk Flow Chain

Owing to the superior quality of our products, we have been listed as a reputed manufacturer and supplier of Bulk Flow Chain. These chain have been designed and developed using top quality components and required raw material. We have appointed a team of professionals who design the product line in such a manner designed in such manner that they efficiently bring motion in pellets. These are used in various industries of the globe giving our customers the best available solution.

Our customized product line includes the below mentioned qualities:

- Durable

- Defect free

- Simple in use

- Easy in handling

- Maintenance free

High-Tensile Strength for Heavy Loads

Designed to withstand significant breaking loads, this bulk flow chain ensures reliable performance in intense, continuous operations. Alloy steel construction provides the durability needed for transporting heavy or abrasive materials in bulk, making it suitable for high-capacity environments.

Customizable Specifications to Match Application Needs

The chain offers flexible pitch, link thickness, and width choices, allowing it to be precisely tailored to client requirements. Available fence widths, lengths, and frame options further promote compatibility with existing conveyor systems and diverse industrial projects.

Enhanced Corrosion Resistance for Extended Service Life

Special corrosion-resistant finishes protect the chain in harsh operating conditions, such as cement plants and mining operations. This feature increases durability and minimizes maintenance frequency, even when exposed to abrasive materials and challenging environments.

FAQs of Industrial Bulk Flow Chain:

Q: How can the Industrial Bulk Flow Chain be customized for specific conveyor applications?

A: This chain can be customized in terms of pitch (standard or custom), chain width (from 50mm to 400mm), link thickness (8mm to 32mm), and overall length, meeting the precise dimensional needs of various conveyor systems.Q: What materials and finishing standards are used for the chain, and how do they benefit industrial users?

A: Manufactured from alloy steel or steel and compliant with ISO 1977, DIN, and AS standards, the chain delivers excellent strength and reliability. Additional corrosion-resistant treatments extend its operational life in tough industrial settings.Q: When is it advisable to use drop forged versus welded steel types of this bulk flow chain?

A: Drop forged chains are preferred for applications requiring extreme strength and shock resistance, while welded steel options are suitable for less demanding but heavy-duty tasks where cost-efficiency is also important.Q: Where is the Industrial Bulk Flow Chain most commonly used?

A: This chain is primarily utilized in mining, cement plants, foundries, and power generation facilities, where reliable bulk material transport is essential for operational efficiency.Q: What is the typical process for ordering a custom configuration of this bulk flow chain?

A: Customers provide their required specificationssuch as pitch, width, thickness, and lengthafter which the manufacturer designs and fabricates the chain accordingly, ensuring compliance with selected standards and application needs.Q: How does the chains enhanced corrosion resistance impact its usage and maintenance requirements?

A: Enhanced corrosion resistance prolongs the chains active lifespan, particularly in abrasive or chemically harsh environments, resulting in fewer replacements and reduced maintenance frequency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Chain Category

Extractor Chain

Price 170.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Mild Steel, Other

Fence Length : Customized

Fittings : Other, Standard Fittings Included

Fence Type : Other, Extractor Chain

Mild steel Chain

Price 170.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Mild Steel

Fence Length : Available in standard and custom lengths

Fittings : Hooks or custom fasteners as required, Other

Fence Type : Other, Chain Type

Bulk Flow Chain

Price 170.00 INR

Minimum Order Quantity : 1 Piece

Material : Other, Alloy steel / Carbon steel

Fence Length : Manufactured as per order specification

Fittings : Other, Supplied with required connecting links and attachments

Fence Type : Other, Industrial conveying chain

Bulk Flow Chain

Price 170.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Alloy Steel

Fence Length : Custom lengths available

Fittings : Other, Standard Chain Attachments

Fence Type : Other, Bulk Flow Chain

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS