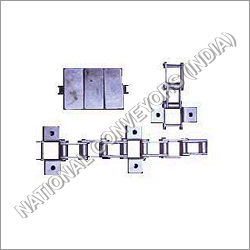

Bulk Flow Chain

Bulk Flow Chain Specification

- Material

- Alloy steel / Carbon steel

- Metal Type

- Stainless Steel / Mild Steel

- Fence Type

- Industrial conveying chain

- Frame Type

- Solid Link / Roller Type

- Fittings

- Supplied with required connecting links and attachments

- Fence Width

- Customizable as per requirement

- Fence Length

- Manufactured as per order specification

- Application

- Bulk material handling, grain conveyors, cement plants, mining conveyors

Bulk Flow Chain Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 10-15 Days

About Bulk Flow Chain

With the assistance of our team of experienced professionals, we manufacture, supply and export Bulk Flow Chain. Owing to our huge infrastructure, we are able to manufacture these products from latest machines and in bulk quantity. These products are mainly used to pull coal, husk, grains and powdery material. Quality is our topmost priority for this, we thoroughly check these products on well-defined parameters. This Bulk Flow Chain is highly appreciated by the patrons for its unmatched features like:

-

Low maintenance

-

Easy installation

-

Corrosion resistance

-

Durable

Other details:

Owing to the superior quality of our products, we have been listed as a reputed manufacturer and supplier of Bulk Flow Chain. These chain have been designed and developed using top quality components and required raw material. We have appointed a team of professionals who design the product line in such a manner designed in such manner that they efficiently bring motion in pellets. These are used in various industries of the globe giving our customers the best available solution.

Our customized product line includes the below mentioned qualities:

-

Durable

-

Defect free

-

Simple in use

-

Easy in handling

-

Maintenance free

Customizable Design for Versatile Applications

Our Bulk Flow Chain is designed with flexibility in mind, offering fully customizable fence widths and lengths to match unique project requirements. Available in both solid link and roller types, along with a choice between alloy, carbon, stainless, or mild steel, these chains cater to a wide range of industrial conveying needs. The robust structure ensures efficiency and longevity in harsh operational conditions, including grain processing, cement manufacturing, and mining operations.

Durable Materials and Reliable Performance

Constructed from high-grade alloy steel or carbon steel, our chains are built to withstand intensive workloads. Select from stainless steel or mild steel metal types to meet specific environmental and operational demands. Each chain is equipped with required attachments and connecting links, ensuring seamless installation. This makes them an excellent choice for industries aiming for durability and consistent performance.

FAQs of Bulk Flow Chain:

Q: How is the fence width of the Bulk Flow Chain customized?

A: The fence width of our Bulk Flow Chain can be tailored exactly to your project specifications at the time of order. You simply provide the required dimensions, and we manufacture the chain to match your precise requirements.Q: What materials are available for the chain and how do they benefit specific applications?

A: We offer the chain in alloy steel, carbon steel, stainless steel, and mild steel. Stainless steel is ideal for corrosive environments, while alloy and carbon steel offer high strength for demanding industrial use. This range ensures the right combination of durability and performance for each application.Q: Where can these Bulk Flow Chains be used effectively?

A: These chains are primarily used in bulk material handling systems including grain conveyors, cement plants, and mining operations. Their robust construction and adaptability make them suitable for many industrial conveying applications across different sectors.Q: What is the process for ordering a customized Bulk Flow Chain?

A: To order, specify your requirements for fence width, length, material, frame type, and any attachments needed. Once your specifications are received, we manufacture the chain exactly to your order and deliver it complete with required fittings.Q: When are the fitting attachments provided with the chain?

A: All necessary connecting links and attachments are included with your chain order, ensuring you have everything needed for straightforward installation and integration with your conveying system.Q: How does using a Bulk Flow Chain improve bulk material handling operations?

A: Using a Bulk Flow Chain ensures reliable, consistent movement of materials, minimizes downtime, and increases operational efficiency. Its robust construction allows it to handle heavy loads and harsh conditions, making it a valuable asset for industrial plants.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Chain Category

Extractor Chain

Price 170.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Other, Industrial Material Handling, Conveyor, Extractors

Metal Type : Steel

Material : Mild Steel, Other

Fittings : Other, Standard Fittings Included

Mild steel Chain

Price 170.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Other, Industrial, Agricultural, Security, Boundary Fencing

Metal Type : Steel

Material : Other, Mild Steel

Fittings : Hooks or custom fasteners as required, Other

Bulk Flow Chain

Price 170.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Other, Bulk material handling in conveyors, elevators, and industrial applications

Metal Type : Steel

Material : Other, Alloy Steel

Fittings : Other, Standard Chain Attachments

Industrial Bulk Flow Chain

Price 170.00 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Other, Bulk material handling in industrial conveyors

Metal Type : Steel

Material : Other, Alloy Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free