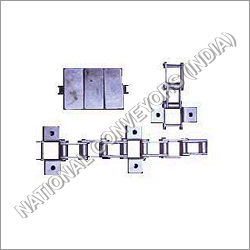

Dryer Cooler Chain

Price 170.00 INR/ Piece

Dryer Cooler Chain Specification

- Material

- Stainless Steel

- Metal Type

- Steel

- Hole Shape

- Oval

- Fence Type

- Chain Link

- Fittings

- Standard

- Fence Length

- Custom

- Application

- Dryer and Cooler Conveyor Systems

Dryer Cooler Chain Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 10-15 Days

About Dryer Cooler Chain

By meeting the small as well as bulk needs of the industry, we are involved in manufacturing, supplying and exporting Dryer Cooler Chain. We are backed by automatic production unit, which helps us in manufacturing defect-free products in bulk quantity. Raw materials that are used to manufacture these products are thoroughly checked by our quality experts to ensure the flawlessness of products. Our esteemed clients can avail this Dryer Cooler Chain from us in varied specifications.

Features of Dryer Cooler Chain:

- Abrasion resistant

- High material strength

- Sturdy built

- Light weight

Other details:

We are a leading business firm instrumental in offering a wide assortment of Dryer Cooler Chain. These are fabricated by a team consisting of skilled and experienced professionals, in compliance with the international norms and standards of quality. We implement and execute every possible step in order to attain maximum satisfaction of valuable patrons. Thus, we offer the quality tested chains according to the client's specifications and requirements.

Our range of chains is highly appreciated and acknowledged in the market for the below mentioned attributes:

- Durability

- High authenticity

- High efficiency

- Resistance to wear & tear

Robust Double Strand Construction

The chains double strand structure provides exceptional strength and ensures reliable performance under heavy-duty conditions. This feature optimizes durability and handling, making the chain suitable for industrial drying and cooling mechanisms that require high load-bearing capacity.

Precision Surface Treatment for Longevity

Each chain undergoes meticulous polishing, resulting in a smooth, corrosion-resistant surface. This treatment enhances the chains resilience in high-temperature environments, prolonging operational life while reducing maintenance needs in demanding manufacturing settings.

Customizable Specifications to Meet Your Needs

With offerings in both standard and tailored pitches, as well as adjustable fence lengths, this chain can be adapted to a wide variety of conveyor systems. Our manufacturing flexibility ensures seamless integration with your existing dryer and cooler infrastructure.

FAQs of Dryer Cooler Chain:

Q: How is the dryer cooler chain installed in industrial drying and cooling systems?

A: The chain is typically integrated into conveyor systems, where its customized pitch and double strand design allow for smooth movement and effective handling of heavy loads. Installation is straightforward with standard fittings supplied, ensuring compatibility with most industrial dryers and coolers.Q: What makes this chain suitable for heavy-duty industrial usage?

A: Constructed from premium stainless steel with a double strand structure, the chain supports substantial weight and withstands operation at temperatures up to 250C. Its robust build and polished finish are especially suited for high-stress industrial environments.Q: When should I consider using a custom pitch or fence length for my application?

A: Custom pitch and fence length options are ideal when standard sizes do not align with your conveyors requirements. Adjusting these specifications ensures the chain aligns perfectly, optimizing system efficiency and reducing wear during operation.Q: Where is the chain manufactured and can it be exported internationally?

A: The dryer cooler chain is manufactured in India, adhering to rigorous quality standards. As both supplier and exporter, we offer worldwide shipping, ensuring reliable delivery in sturdy wooden box packaging.Q: What is the process involved in the surface treatment of the chain?

A: Each chain undergoes a specialized polishing process that enhances its surface finish, delivering corrosion resistance and extended durability, especially necessary in humid or high-temperature industrial environments.Q: How can I benefit from using a stainless steel dryer cooler chain in my facility?

A: Stainless steel construction ensures superior resistance to corrosion and temperature extremes. This not only extends the lifespan of your conveyor system but also minimizes maintenance downtime, improving overall production efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Chain Category

Mild steel Chain

Price 170.00 INR / Piece

Minimum Order Quantity : 1 Piece

Metal Type : Steel

Application : Other, Industrial, Agricultural, Security, Boundary Fencing

Material : Other, Mild Steel

Fence Length : Available in standard and custom lengths

Redler Chain

Price 170.00 INR / Piece

Minimum Order Quantity : 1 Piece

Metal Type : Other, Carbon Steel

Application : Other, Bulk material handling, Redler conveyors

Material : Other, Mild Steel

Fence Length : Custom length available

Bulk Flow Chain

Price 170.00 INR

Minimum Order Quantity : 1 Piece

Metal Type : Other, Stainless Steel / Mild Steel

Application : Other, Bulk material handling, grain conveyors, cement plants, mining conveyors

Material : Other, Alloy steel / Carbon steel

Fence Length : Manufactured as per order specification

Bulk Flow Chain

Price 170.00 INR / Piece

Minimum Order Quantity : 1 Piece

Metal Type : Steel

Application : Other, Bulk material handling in conveyors, elevators, and industrial applications

Material : Other, Alloy Steel

Fence Length : Custom lengths available

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free